Elvis Presley played here four times in 1955 and 1956. Jimi Hendrix played downtown’s Curtis Hixon Hall twice in 1968, and Tampa police arrested Janis Joplin after her concert at the same venue a year later for indecent language.

There’s also Dean Guitars, which has been quietly making custom six-strings by hand for globe-trotting rockstars at its Carrollwood factory for over a decade. The Chicago-born company was founded back in 1976 by Dean Zelinsky, who quickly made inroads with massive artists like The Cars and ZZ Top. The furry guitars in the band’s 983 “Legs” music video? Custom Dean Guitars.

But the success didn’t last. In 1995, Elliott Rubinson bought the Dean Guitars name and moved the company to his adopted hometown of Tampa Bay. By 2007, Dean outgrew its Clearwater space and relocated to its current 118,000-square-foot Tampa warehouse. After growing up in Tampa, Rubinson’s only child, Evan, moved away for college and landed in New York City, where he began operating his own hedge fund. But in 2016, Evan got the call that changed his life. His father had been diagnosed with an aggressive form of brain cancer at 62. Rubinson returned to Tampa and took over as company CEO shortly before his father passed away.

“I had kind of grown up in the industry, but I had never worked intimately in it other than working summers in the warehouse,” Rubinson says. “For me, taking over was a lot to learn.”

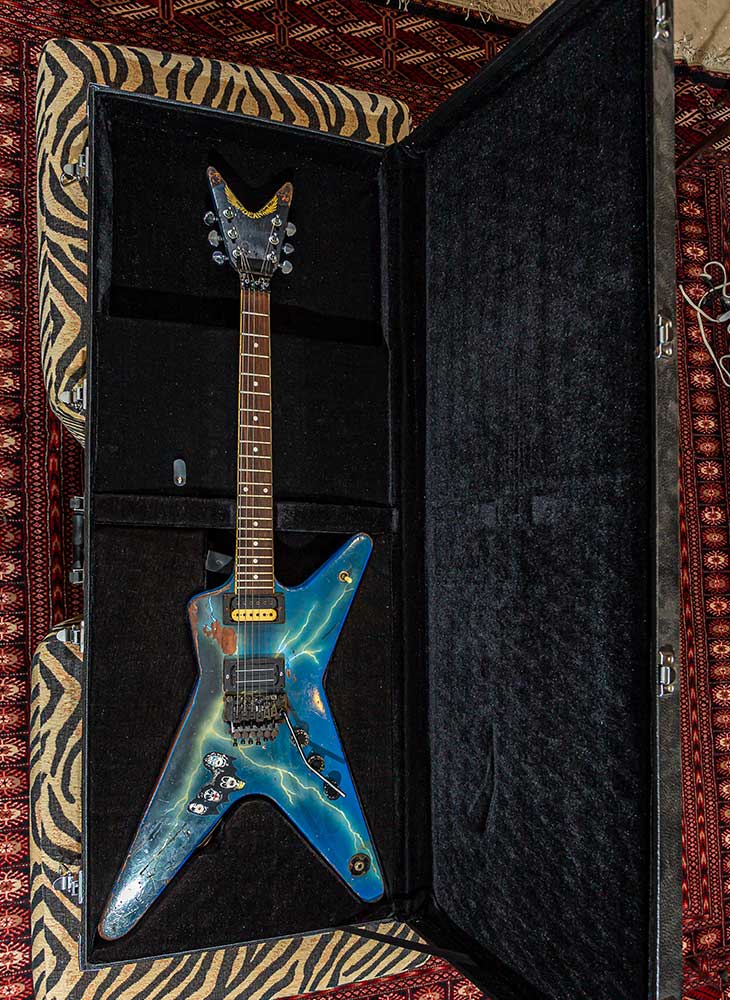

He soon found his footing, and Dean Guitars (along with its holding company, Armadillo Enterprises, which also comprises Luna Guitars and DDrum percussion) is flourishing. The Tampa facility produces the high-end, custom guitars seen in the hands of musicians like Dave Mustaine from the band Megadeth and Kerry King of Slayer. Dean’s craftsmen — some of whom have been with the company since the 1990s — source the wood that become the bodies, necks and tops of its guitars. They oversee the CNC machine, which is programmed to carefully cut out the guitar body, making adjustments as needed to the only automated step of Dean’s process. The company started with four classic body shapes from which the rest of its guitars have evolved. One of them, the Cadillac, has never been replicated by another guitar maker.

After the body is complete, the next craftsman will smooth and contour the guitar’s curves by hand. Another then carefully binds the neck, inserts the frets (where the guitar is actually played) and completes the inlay on the fretboard. “Some people want their initials, some people want their kids’ names,” Rubinson says. “The inlays can be very intricate.”

While the company is opening a Tampa paint shop in the coming months, it currently ships custom guitars out to be hand-painted in California. Upon the guitar’s return, Dean’s craftsmen add the final touches and wiring. Rubinson says Dean’s key differentiator is its “just right” size. Dean is big enough to have salespeople on every continent, reaching artists wherever they happen to be, but is small enough for artists to be able to have a personal connection with its whole team.

“Everyone makes a block of wood and six strings. If you do that well and you have good engineers, then you have a good guitar,” Rubinson says. “[But if I play a Dean guitar], that means I get to talk to the CEO. I get to talk to the head luthier (craftsman) that’s making my guitar on a daily or weekly basis… I think what drives us and what allows us to be better than the competition is that family oriented aspect.”

Theoretically, Dean could be headquartered anywhere in the United States, Rubinson says. But just like his company offers its artists the resources of a large company and the comforts of a small one, Tampa strikes the perfect balance for a manufacturer.

“It’s the perfect storm. It’s a metropolis… It’s a burgeoning area, but at the same time it’s not so big that it’s [cost-prohibitive] to be able to have a 118,000-square-foot warehouse,” like it might be in New York or Los Angeles, he explains.

And while 2020 has been a successful one for his company (thanks to people staying home and picking up an acoustic guitar or ukulele), it has been the opposite for the artists who have partnered with Dean Guitars. Rubinson and his team have doubled down on their family-style business model, having artists sign guitars, connecting them with fans through virtual Q&As and providing them with other opportunities to make a bit of money while they can’t tour. In the same way Tampa has been there for his company, Rubinson wants to give a boost to artists in need and keep them, and Dean Guitars, moving forward.

“I have that long-term vision [for artists] of, this is what you can be, and this is what you should be,” Rubinson says. “We’re not going to let short-term things like coronavirus or no touring affect what that overall trajectory should look like.”