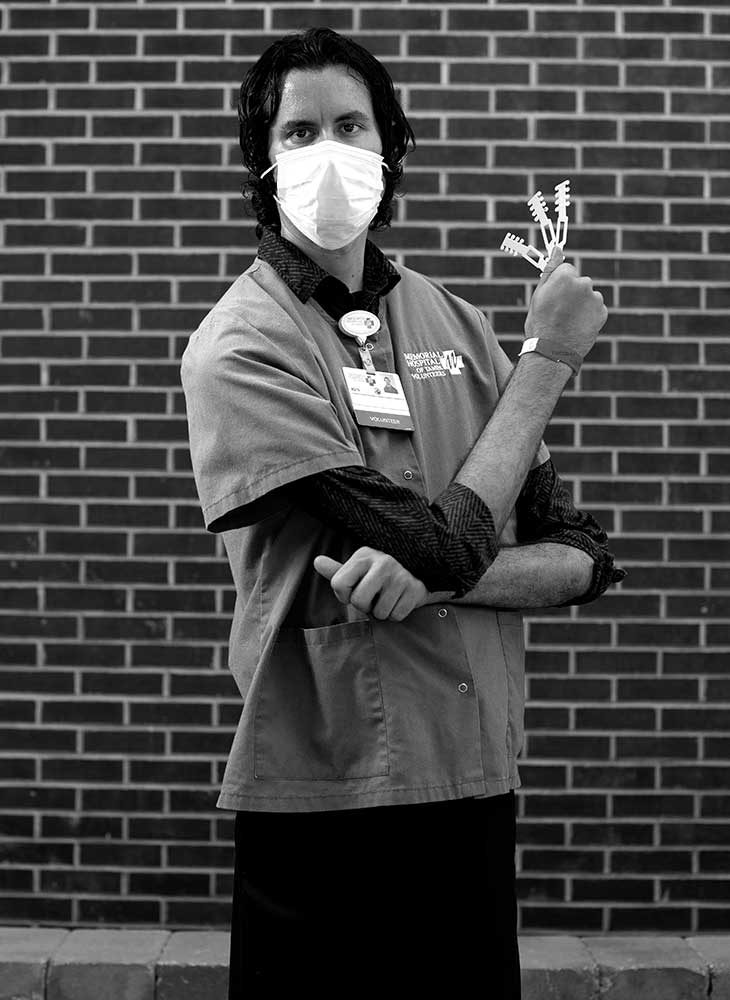

Ben Brittain is a self-described tinkerer at heart. A microbiologist by trade, Brittain started playing around with 3D printing a few years back to create small tools that made his lab projects easier. Brittain has also volunteered at Memorial Hospital Tampa in his free time since 2017, but the program was shut down at the onset of the pandemic.

So when he saw the project files for a small, comblike piece of plastic designed to make wearing face masks more comfortable on an open-source 3D printing website, he had a thought. He printed off a few of the “surgical mask tension release bands” for his girlfriend, a nurse, to test-drive.

“She loved them. They really help with keeping the mask off your ears, especially after long shifts,” Brittain says. “I [realized] these would be great for Memorial.”

By the beginning of April, the design for the earguards — which lift the bands of the mask off the ears, relieving tension — had been approved by the National Institutes of Health. Brittain printed off 100 earguards made from corn-based PLA plastic filaments, sterilized them with alcohol, and presented them to Linda Reece, who coordinates Memorial Hospital’s volunteer program.

The hospital confirmed that the earguards met its sterility and safety guidelines and quickly asked Brittain to make more for its employees. “It was just an overwhelmingly positive response,” he says. “That was really encouraging, and I’m glad to see something I just started as kind of a hobby and is only tangentially work-related become so beneficial.”

The guards were especially helpful for non-medical employees for whom frequent mask-wearing was new. “My ears hurt from wearing a mask all day and having the ear guard makes it so much more comfortable,” says Cindy Jackson, Memorial Hospital’s food and nutrition supervisor.

Brittain prints five guards at once, which takes about an hour. He says the process of sending a file to print in 3D printing works similarly to a traditional ink-jet printer. He’ll put in one plate to start printing when he goes to work in the morning, then a new one at lunch, a new one when he gets home in the evening, and so on.

Since the beginning of the pandemic, Brittain estimates he’s made about 350 guards. The PLA filament is cheap, and he already had a 3D printer, making time his only real investment in the project. He plans to continue making the earguards as long as Memorial Hospital has a use for them.

“This is something that, if I can do it, so many people can do it. We maybe can’t make the masks, we can’t make other things that are more complex, but really a lot of people can make these,” Brittain adds. “It’s great because we can’t volunteer right now, so it was something I could donate more time doing and kind of help in any way I can.”